GC Injection Valves - Up to 14 Ports

Pneumatic, electric or manual-operated

Description

Injection valves for gas chromatography (GC), VOC analysis, petrochemical switching, and gas sampling processes. These valves can optionally be equipped with a purge function.

- Rotor surface-treated to prevent adhesion and reduce torque

- Temperature resistance: 200 °C

- Pressure resistance: 6.9 bar | 100 psi (gas)

- Up to 14 ports

- Orifice sizes: 0.40 mm, 0.75 mm, 1.0 mm

- Rotor material: Nitronic 60 (additional optional materials available, e.g., Hastelloy alloys)

- Extension rods: 2", 3", 4", 6"

- Optional: Rotor surface passivation

Valve versions with purge function for ultra‑pure gases and toxic gas samples

Thanks to the integrated purge function, these valve variants are ideally suited for ultra‑pure gases as well as toxic gas samples. External purging with a protective gas reliably shields the sample from environmental influences and prevents both the ingress of ambient air and the possible escape of the sample medium. This makes the valves an excellent choice for applications involving toxic, flammable, or explosive gases.

Specifications

Thread types

|

10-32 UNF | 1/4/28 UNF | 6-40 UNF

|

Orifice diameter

|

0.40 mm | 0.75 mm | 1.0 mm

|

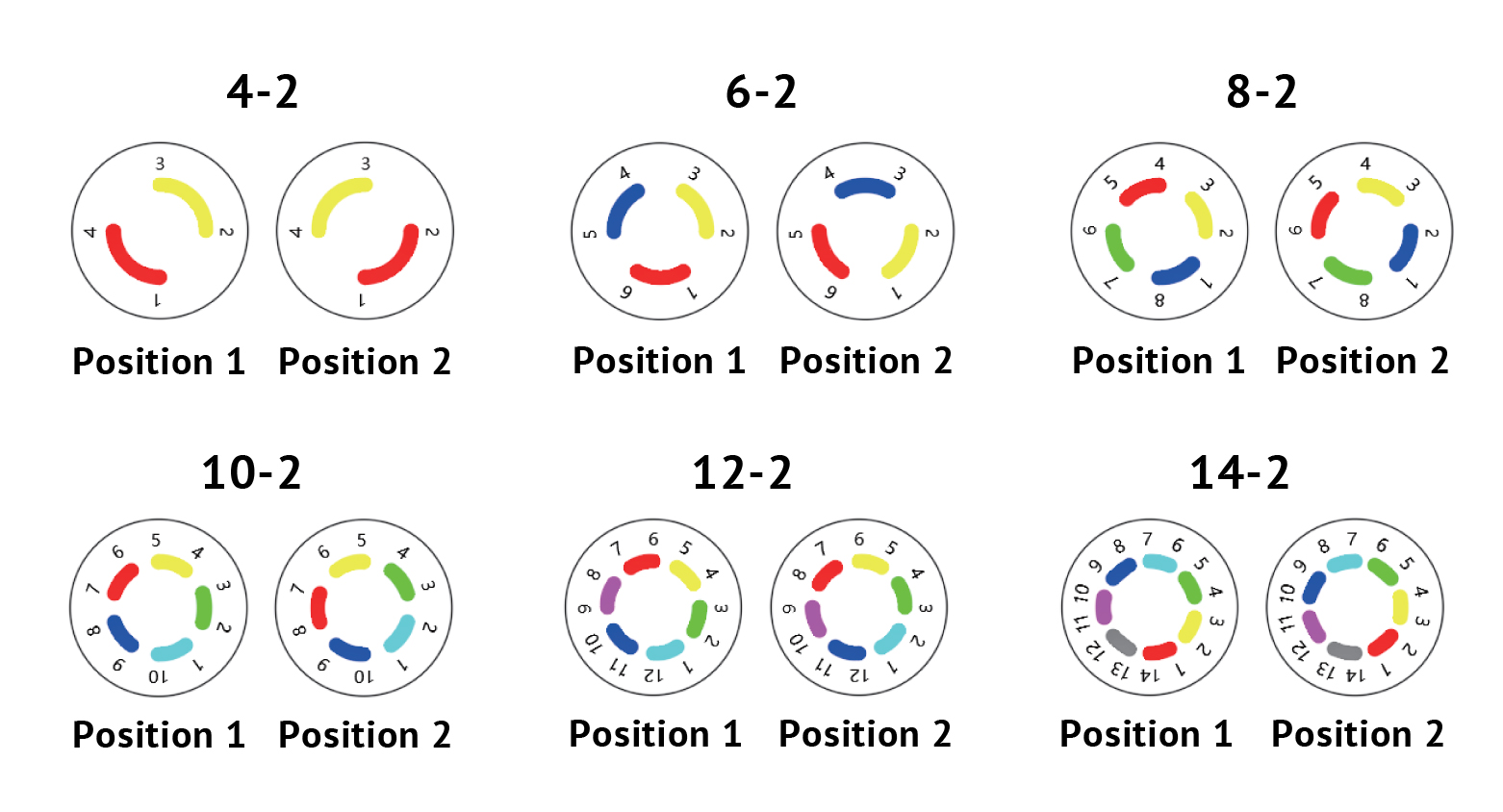

Number of ports

|

4 | 6 | 8 | 10 | 12 | 14

|

Rotor material

|

Nitronic 60 (standard) | SUS316L | Hastelloy C | Hastelloy B

|

Maximum pressure

|

6.9 bar (100 psi) (gas)

|

Operating temperature

|

0 – 200 °C

|

Extension rods

|

2" | 3" | 4" | 6"

|

Actuation type

|

Pneumatic, electric, manual

|

Pneumatic pressure

|

2.75 – 5.5 bar (40 – 80 psi) (for pneumatic version)

|

Operating voltage

|

24 VDC ±10% (for electric version)

|

Communication interfaces

|

RS232 | RS485 (for electric version)

|